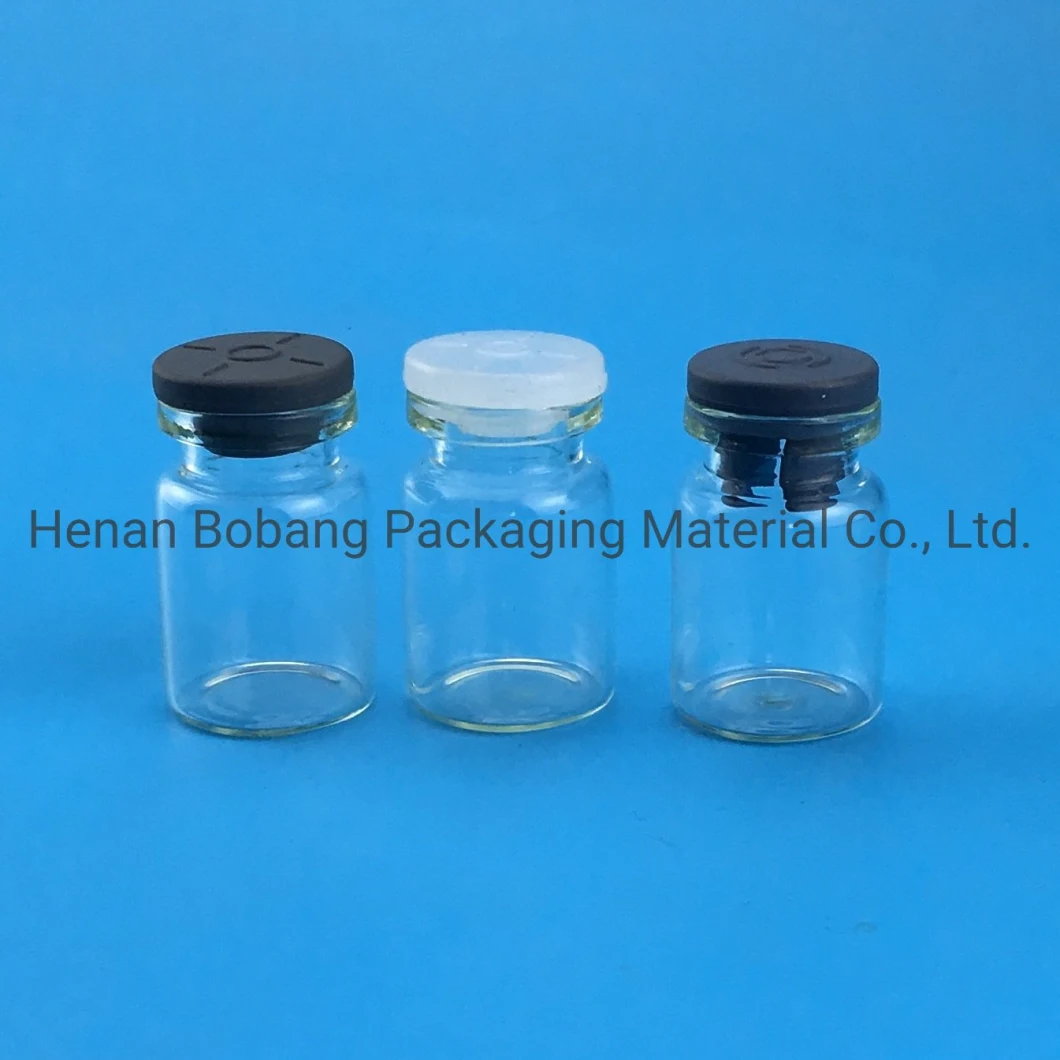

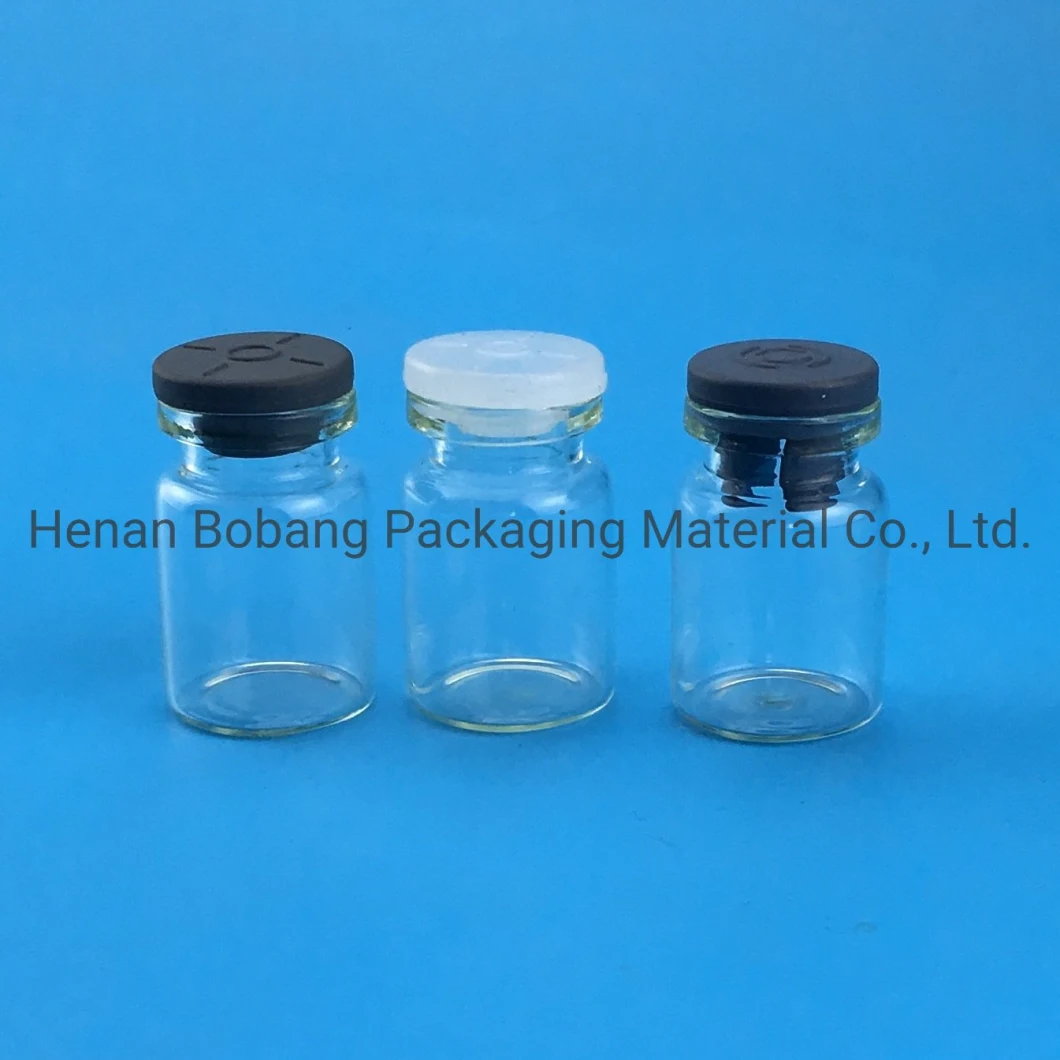

Empty Glass Vials 6ml amber tubular vials

Glass Vials Manufacturer

. Fill in product labels and production records online by employees to ensure that each batch of products is documented;

· Product online production, equipped with computer numerical control system or real-time tracking and monitoring by operators;

· Quality inspectors conduct systematic random checks on the physical properties of finished ampoules such as appearance, height and breaking force;

· The laboratory is responsible for checking the content of boron trioxide and the water resistance of the particles in the finished product.

Production Workshop from Bobang

Packing and Delivery

Packing and Delivery

Bobang can provide customized packages for Vial

Glass Vials Manufacturer

Henan Bobang Packaging Material Co.,Ltd (Ampoule,vial manufacture)

offers a broad portfolio of highly competitive pharmaceutical ampoule in type I pharma glass. Our standard range covers ampoule made of flint and amber glass with filling capacities from 1 to 30 ml. These include straight-stem, funnel-type and closed ampoule of ISO types B, C and D with various break systems such as OPC (One Point Cut), CBR (Colour Break Ring) and Score Ring. In addition to the ISO norms customized shapes are available on request.

Bobang also distribute glass vials, glass ampoules, glass test tubes, flip off caps, rubber stoppers, pre-filled syringes, infusion bags and glass tubes.

Welcome come to visit our factory.

Quality Inspection buy from Bobangoffers a broad portfolio of highly competitive pharmaceutical ampoule in type I pharma glass. Our standard range covers ampoule made of flint and amber glass with filling capacities from 1 to 30 ml. These include straight-stem, funnel-type and closed ampoule of ISO types B, C and D with various break systems such as OPC (One Point Cut), CBR (Colour Break Ring) and Score Ring. In addition to the ISO norms customized shapes are available on request.

Bobang also distribute glass vials, glass ampoules, glass test tubes, flip off caps, rubber stoppers, pre-filled syringes, infusion bags and glass tubes.

Welcome come to visit our factory.

. Fill in product labels and production records online by employees to ensure that each batch of products is documented;

· Product online production, equipped with computer numerical control system or real-time tracking and monitoring by operators;

· Quality inspectors conduct systematic random checks on the physical properties of finished ampoules such as appearance, height and breaking force;

· The laboratory is responsible for checking the content of boron trioxide and the water resistance of the particles in the finished product.

Production Workshop from Bobang

Packing and Delivery

Packing and DeliveryBobang can provide customized packages for Vial